新闻中心

半导体干法刻蚀后、清洗去胶液,替代ATMI ST-250英特

发布日期:2024/11/26 16:48:12

浏览次数: 点赞数: 收藏数: 关注数: 【赞一个】 【举报】 【收藏】 【关注】 半导体干法刻蚀后、清洗去胶液,替代ATMI ST-250英特格Post-Etch Residue

Removal Solution半导体干法刻蚀后清洗去胶液,替代ATMI ST-250(英特格)

深圳市芯泰科光电有限公司

产品热线许经理 :13玖23八66554 扣扣:35捌9123零

深圳市芯泰科光电有限公司,创立于2014年,是一家服务于微电子领域的产品贸易及技术服务提供商。我们已经成为国内微电子制程领域和相关大学研究所信赖的合作伙伴;公司秉持以忠诚态度对待新旧客户,以客户满意为导向,提供优质高效率的专业服务,提供产品行销及技术支援解决方案。我们目标是成为一家新材料应用技术推广服务的专业供应商。

Post-Etch Residue

Removal Solution

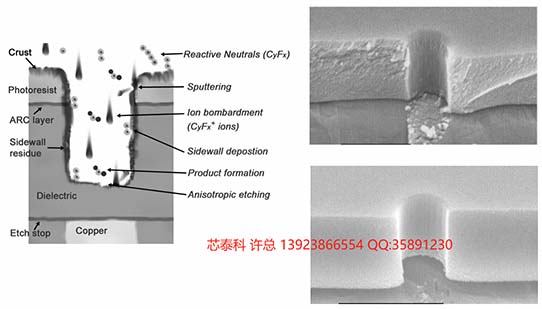

Origin Example of Post-Etch Residue

Fluorocarbon post-etch residue characterization

Residue type: PR residues, PR crust, post-ash residue (Carbon contained

organic polymers), plasma post-etch residue (X contained

oxides polymers), metal oxides, Si-oxides, metal complex….

Strategy for Post-Etch Residue Removal

1. Surface wetting: surfactant additive to lower down

surface tension of cleaning solution

2. Solvent Dissolution: dissolve organic residue polymers

3. Degradation: controlled wet-etching to remove inorganic

reside

4. Coordination: forms metal-lig complex compounds to

remove metal containing residue

5. Corrosion control: use corrosion inhibitor to prevent

damage to metals, dielectrics, other materials

ZS-750 Residue Remover Design Concept

1. Capable to remove all post-etch residue at RT~50oC

2. Short process time

3. Buffered solution to keep alkaline pH

4. Nodamage to dielectric materials

5. No Cu corrosion

6. Electronic grade clean solution

7. Compatible to wet bench SWT

8. Excellent bath life

9. HDA-free

Amines Alkaline pH buffer, organic residue remova

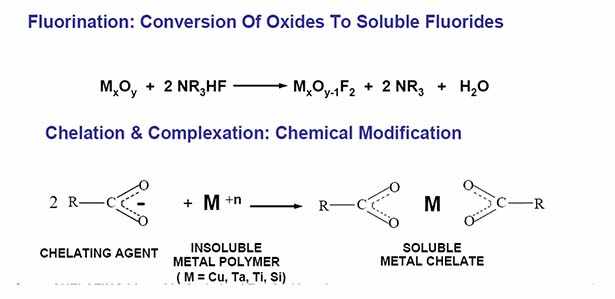

Fluoride Inorganic residue degradation

Metal chelator Metal oxide/ion removal, buffer

Surfactant Organic inorganic residue removal, surface wetting

Corrosion Metal corrosion control surface conditioning

Inhibitor

Pourbaix

in

diagram for copper

uncompld media

Copper corrosion can be controlled better in alkaline pH environment!

Surface Wetting Phenomen

a

Surface wetting is critical mechanism to bring cleaning solution to contact with

small dimension structure surface to ensure well reaction between effective

ingredients residues!

Coordination Chemistry to Dissolve

Metal-containing Residues

Recommended Process Temperature Range

1. Recommended process temperature for ZS-750 is

30~60oC.

2. Spray performance is not good enough for SWT due to

higher viscosity of cleaning solution.

3. Reactions may not be activated well enough to remove

residues at temperature lower than 30oC.

4. Higher process temperature may cause faster metal (Cu)

oxidation in ambient atmosphere (O2 presence) which

resulted in higher etch rates

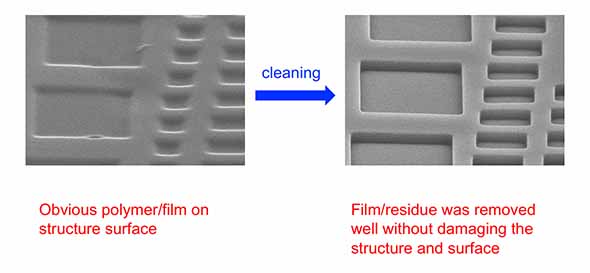

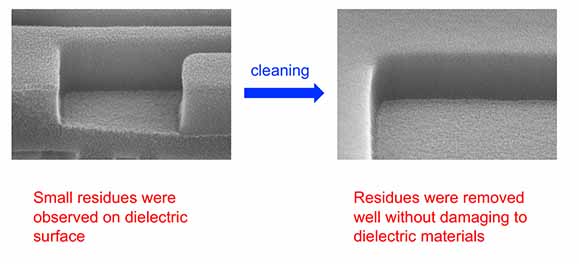

Cleaning Performance Example 1

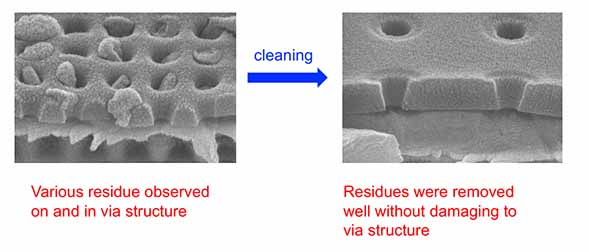

Cleaning Performance Example 2

Cleaning Performance Example 3

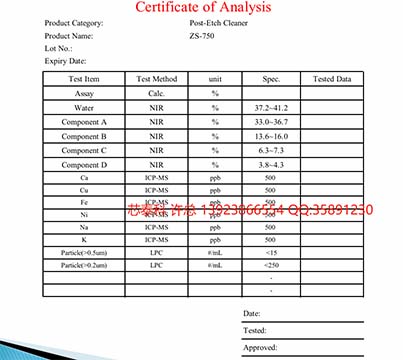

Quality Control Items CoA

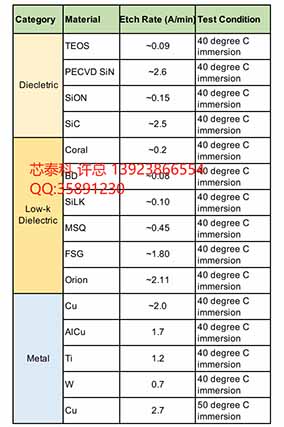

ZS-750 Etch Rates

to Blanket Films

Tested by immersing coupons into ZS-750

at ambient lab environment followed by direct

DIW rinse CDA drying.

Process Tools Bath Life

1. ZS-750 can be used in immersion wet bench or

spray-type single wafer tools (SWT).

2. ZS-750 bath life is up to 96 hrs or longer!

3.Major failure mechanism is water content change

due to evaporation or moisture absorption/bring-in

wafer loadings.

4. Water content monitoring replenish is helpful

to bath life extension