新闻中心

半导体铜制程、CMP后清洗剂,替代ATMI ESC-784英

发布日期:2024/11/26 16:48:12

浏览次数: 点赞数: 收藏数: 关注数: 【赞一个】 【举报】 【收藏】 【关注】 半导体铜制程、CMP后清洗剂,替代ATMI ESC-784英特格深圳市芯泰科光电有限公司

产品热线许经理 :13玖23八66554 扣扣:35捌9123零

深圳市芯泰科光电有限公司,创立于2014年,是一家服务于微电子领域的产品贸易及技术服务提供商。我们已经成为国内微电子制程领域和相关大学研究所信赖的合作伙伴;公司秉持以忠诚态度对待新旧客户,以客户满意为导向,提供优质高效率的专业服务,提供产品行销及技术支援解决方案。我们目标是成为一家新材料应用技术推广服务的专业供应商。

ZS-800 Series

Post CMP Cleaning Solutions

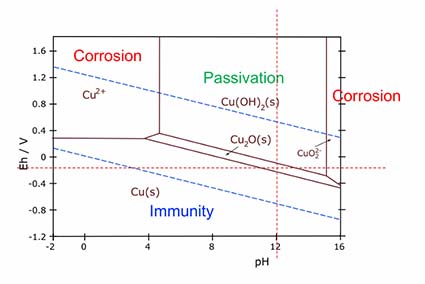

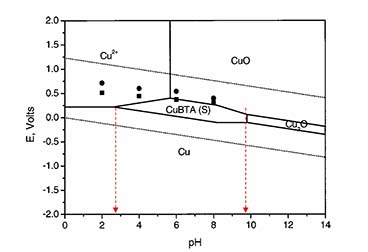

Pourbaix

diagram for copper in uncompld media

Redox pH condition are critical to Cu surface treatment formulation design!

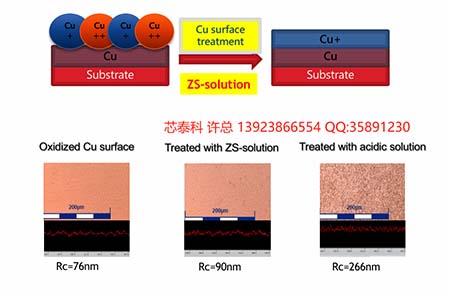

Controlled treatment to oxidized Cu surface

Critical to PCMP Cleaning Solution Design

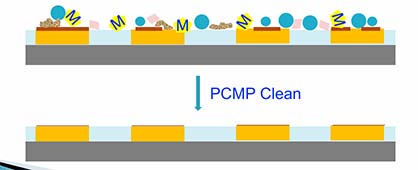

1. Particle removal: abrasive materials slurry

2. Organic residue removal: polymers, BTA, ligs….

3. Metal complex inorganic residue removal

4. Safe to other film materials: SiOx, SiN, dielectric…..

5. Cu corrosion inhibition

6. Cu surface conditioning

Pourbaix

diagram for copper-BTA system in water

Cu-BTA complex solid is s between pH 3~10. Cleaning solutions with

pH higher than 10 or lower than 3 are capable to remove Cu-BTA complex!

CEMI ZS-800 Series Design Concepts

1. Buffered high pH solution

2. Reducing agent to control solution electrochemical property

3. Metal chelators to remove metal oxides/ions

4. Surfactants to remove organic inorganic residues

5. Corrosion inhibitors to minimize Cu corrosion

6. Concentrated aqueous solution for cost effectiveness

TMAH/H2O pH adjuster, buffered aqueous, Cu-BTA complex removal

(KOH)

Reducing agent Electro-potential control, buffer, Cu reducing

Metal chelator Metal oxide/ion removal, Cu-BTA complex removal

Surfactant Organic inorganic residue removal, surface wetting

Corrosion Cu corrosion control surface conditioning

Inhibitor

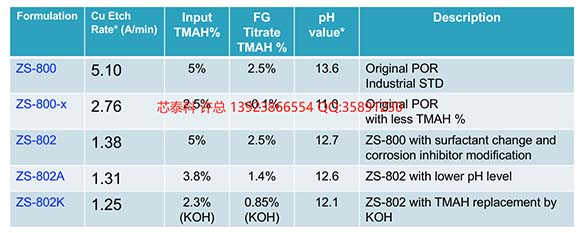

CEMI ZS-800 Series Solution Comparison

1. Dilution ratio can be tailor to customer process need.

2. CIP formulation with same concept can be tailor to customer requirements.

3. Actual TMAH% in Finished Good can be determined through titration.

4. ZS-800 equivalent POR reported actual TMAH% not input value.

5. ZS-802 formulation adopted an optimal buffer system to achieve lower Cu etch rate.

6. Local manufacturing in Taiwan.

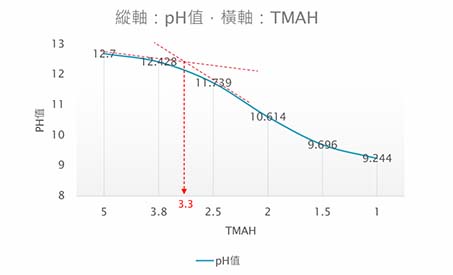

CEMI ZS-802 Series pH Variation

1. Lowest good TMAH input amount of ZS-802 is 3.3%.

2. TAMH input amount is determined to be 3.8% for ZS-802 formulation design.

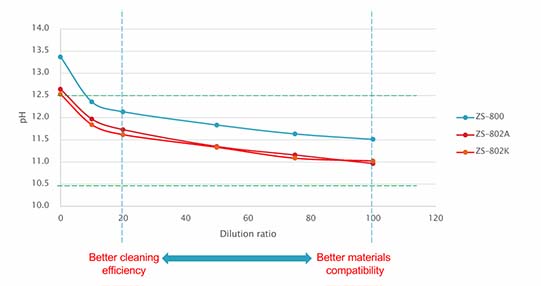

CEMI ZS-800 Dilution Ratio & Application Window

1. Excellent buffer property upon dilution is needed to ensure good performance.

2. ZS-800 series cleaning solution can be used at >100X dilution.

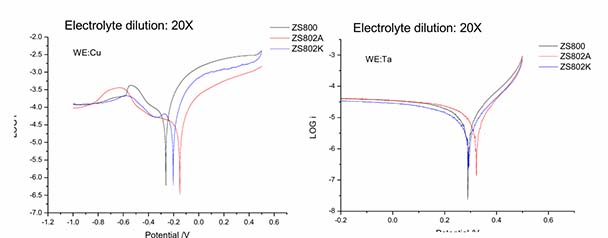

Tafel Plot Using ZS-800 Series as Electrolyte

Copper has lower corrosion rate in ZS-802A&ZS-802K than ZS-800 (POR).

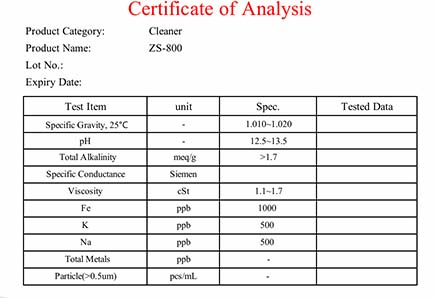

CEMI ZS-800 Series Specs & CoA