半导体、板基封装用、干膜去胶液、剥离液

发布日期:2024/11/26 16:48:12

浏览次数:

点赞数:

收藏数:

关注数:

【赞一个】 【举报】 【收藏】 【关注】

半导体、板基封装用、干膜去胶液、剥离液

深圳市芯泰科光电有限公司

产品热线许经理 :13玖23八66554 扣扣:35捌9123零

深圳市芯泰科光电有限公司,创立于2014年,是一家服务于微电子领域的产品贸易及技术服务提供商。我们已经成为国内微电子制程领域和相关大学研究所信赖的合作伙伴;公司秉持以忠诚态度对待新旧客户,以客户满意为导向,提供优质高效率的专业服务,提供产品行销及技术支援解决方案。我们目标是成为一家新材料应用技术推广服务的专业供应商。

Dry Film Photoresist Stripper ZS-220 for ASE

Outline

? 1. Dry film photoresist working mechanism

? 2. Process temperature vs process time

? 3. Water content (moisture level) vs stripping performance

? 4. Bath-life study without wafer loading

? 5. Bath-life study with wafer loading

? 6. Metal corrosion study

? 7. ZS-200 failure mode & root cause

? 8. Monitoring method

? 9. Strength of ZS-200

? 10. ZS-200 process control flow

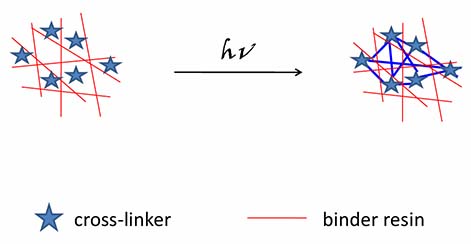

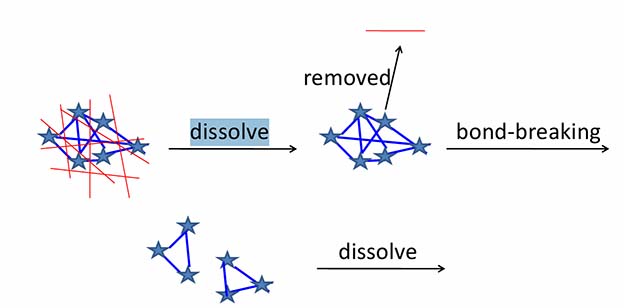

Dry film

Photoresist Working Mechanism

Dry film Photoresist

Stripper

Working

dissolve

Mechanism

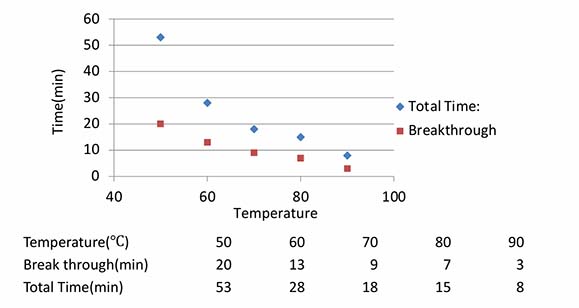

Process temperature

vs process time

Process tool: beaker with stirrer

? Test vehicle: ASE test wafer coupon (2.5x4cm)

dipping in 50g stripper

? Metrology: Optical microscope

? Split condition test procedure:

– Process temperature: 50 to 90 C

– Record break through time

– Residual PR amount compariso

Process temperature

vs process time

ZS-200 is capable to strip off ASE dry-film resist within 50~90C.

Shorter process time required for higher temperature.

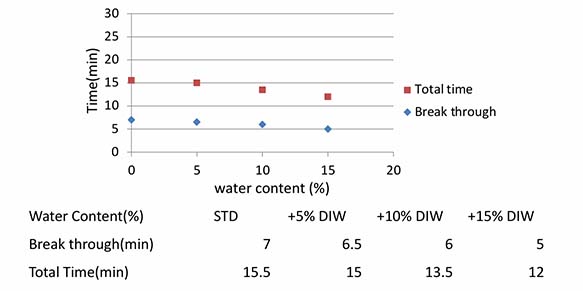

Water content (moisture level)

vs

stripping performance

Process tool: beaker with stirrer

? Test vehicle: ASE test wafer coupon(2.5x4cm)

? Metrology: Optical microscope

? Prepare 4 stripper sample with different H2O

contents:

– (1) stard (2) +5% DIW (3) +10% DIW (4) +15% DIW

? Test stripping time PR removal performance

by break trough time residual PR amount

Water content

vs stripping performance

Performance of ZS-200 is not sensitive to water content. Higher water content

resulted in a little shorter process time but may have lower resist loading

shorter bath-life.

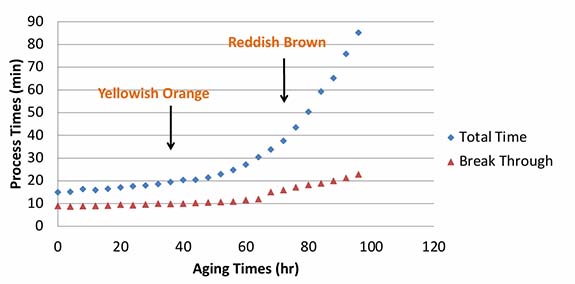

Bath-life study without wafer loading

Process tool: beaker with stirrer (w/o cover)

? Test vehicle: ASE test wafer coupon (2.5x4cm)

? Metrology: Optical microscope

? Heat the stripper bath to 70C up to 48 hours

? Record evaporation amount every 4 hours

? Collect 200mL sample every 4 hours

? Do PR stripping capability test using the

collected stripper samples

Bath-life study without wafer loading

ZS-200 bath life without wafer loading: 72°C

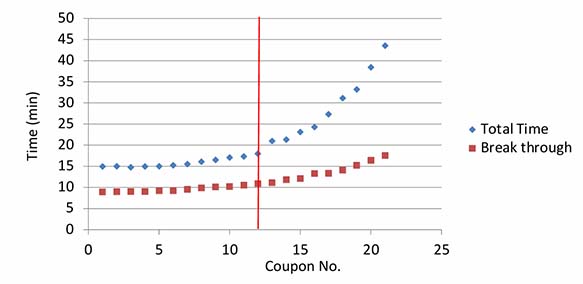

Bath-life study with wafer loading

Process tool: beaker with stirrer (w/o cover)

? Test vehicle: ASE test wafer coupon (2.5x4cm)

? Metrology: Optical microscope

? Heat the stripper bath to 70C

? Do 1 coupon stripping in beaker each time

continuously up to 20 coupons

Bath-life study with wafer loading

ZS-200 bath life with wafer loading: 12hr

Metal corrosion study by analyzing dissolved

metal contents in stripper bath

Process tool: beaker with stirrer (w/o cover)

? Test vehicle: ASE test wafer coupon (2.5x4cm)

? Metrology: ICP-AES

? Do 1 coupon (2.5x4cm) stripping in 100mL

bath for each split condition

? Collect stripper sample do metal contents

analysis using ICP-AES

Metal corrosion study by analyzing dissolved

metal contents in stripper bath

ZS-200 Failure Mode & Root Cause

Incomplete Photoresist Removed

a. Solubility saturation

(1) Photoresist solid content too high

(2) H2O out of range

b. Air oxidation/thermal degradation of bond-breaking agent

?Metal Film Corrosion

a. pH increase due to increase of H2O%

b. Air oxidation/thermal degradation of corrosion inhibitor

Monitoring Method

1. H2O content: Karl-Fischer titration

2. Amine content: pH meter titration

3. Metal corrosion: Cu etch rate

Strength of ZS-200

?High bp, low evaporation:

– No/low odor at process

– Low volatile consumption/low VOC pollution

– Longer bath life

? No hazardous component used:

– No NMP, no DMAc, no DMF, no catechol

? Low waste treatment concern:

– No DMSO or any sulfur

-containing component

(cause waste water treatment issue)

– All components can be incinerated (low waste

treatment cost)

Strength of ZS-200

?Performance is not sensitive to H2O content:

– Large H2O tolerance window

– No severe environmental control necessary for

processing

– Easy to control product (ZS-200)

spec/performance

? Low metal corrosion:

– Extremely low Cu loss in stripping process

– Low Al loss

ZS-200 Process Control Flow